Article: Plastics Engineering

Sensor Products Inc

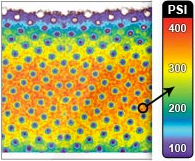

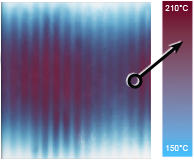

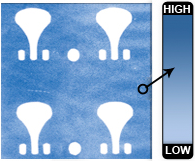

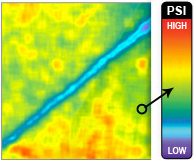

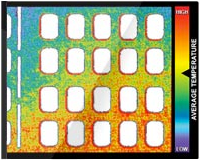

Sensor Products Inc. (Madison, New Jersey, USA) says that its new Mold-Align® tool helps improve yields and reduce defects in the injection-molding process. When placed between mold halves, it instantaneously changes color to reveal how pressure is being distributed between the A&B halves of the mold. �With Mold-Align®, the process is quick and simple,� the company says. �It is placed between platens on the parting line, which are then subjected to pressure upon clamp closing using minimal clamp tonnage. It is then removed and the image [is] inspected for pressure distribution and void spots. [Adjustments, if necessary, are then made] to the platens to achieve alignment, open vents or repair mold damage. Properly mating parting lines and aligned platens reduce machine wear and improve quality. Mold-Align® may be archived and used as a control for comparative purposes.�