Article: New Equipment Digest

Sensor Products Inc: DigiNip® Provides Breakthrough in Narrow Nip Roller Alignment

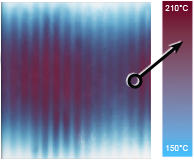

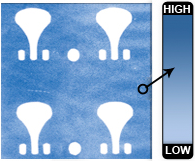

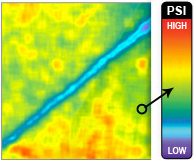

Sensor Products Inc. introduces DigiNip®, an economical hand-held device that transforms the way nip measurements are obtained for small printing, coating, laminating and production rollers. With DigiNip® even a first-time user can instantly and precisely measure spot nip (the contact point between rollers) at any section of a web or sheet fed process. When the unit�s two durable sensor elements are placed between two contacting rollers that are subjected to pressure, nip width readings are immediately displayed on the device.

Real-time roller adjustments for parallelism can then be made quickly and conveniently.

DigiNip® sensor elements placed between two contacting rollers

Unlike traditional methods of measurement - such as inking rollers and carbon paper - that are time consuming and often inaccurate , DigiNip® is clean, reliable, and convenient. Nip width readings are revealed immediately on the digital display, while the nip is closed leading to significant time savings. As a quality control and maintenance tool, it extends roller life thereby decreasing costs. Product quality is also improved.

�Our goal was to provide printers and other web-based industries with a maintenance instrument that can economically diagnose planarity issues and fit in the palm of their hand,� says Jeffrey G. Stark, CEO of Sensor Products Inc. �DigiNip® represents the culmination of years of research in nip measurement.�

The unit includes the hand-held device, two sensor elements, cables, AA batteries and a water resistant carrying case.